- Home

- Stainless Steel Wire Rope

Stainless Steel Wire Rope

Already know what you need? Scroll down to our selection of over 60 styles and sizes.

The Ultimate Guide to Choosing and Maintaining Stainless Steel Wire Rope

Are you looking for the perfect wire rope for your project? Look no further than stainless steel wire rope! With its unparalleled strength and durability, stainless steel wire rope is the ideal choice for a wide range of applications. Whether you need it for lifting heavy loads, securing structures, or even for decorative purposes, stainless steel wire rope provides the reliability and performance you need. In this comprehensive guide, we will take you through everything you need to know about choosing and maintaining stainless steel wire rope. From understanding different grades and constructions to determining the right size and configuration for your specific needs, we've got you covered. We'll also provide expert tips on proper installation and regular maintenance practices to ensure the longevity and performance of your stainless steel wire rope. Choosing the right wire rope can make all the difference in the success of your project. So, let us help you navigate the world of stainless steel wire rope and make an informed decision. Read on to discover the ultimate guide to choosing and maintaining stainless steel wire rope.

Benefits of using stainless steel wire rope

Stainless steel wire rope offers a multitude of benefits that make it the preferred choice for many industries and applications. Firstly, stainless steel wire rope is incredibly strong and durable, making it perfect for heavy-duty tasks. It can withstand high loads and harsh environmental conditions without compromising its structural integrity. Additionally, stainless steel wire rope is resistant to corrosion, rust, and other forms of degradation, ensuring a longer lifespan compared to other materials. Its resistance to chemicals and UV rays further enhances its durability, making it suitable for both indoor and outdoor use. Lastly, stainless steel wire rope is highly flexible and easy to handle, allowing for smooth installation and operation. Not only does stainless steel wire rope offer exceptional strength and durability, but it also provides excellent versatility. It can be used in a wide range of applications, such as lifting and rigging, architectural and design purposes, marine and offshore operations, and even in the food and beverage industry. Its versatility makes it a popular choice among professionals in various fields, as it can be customized to meet specific requirements.

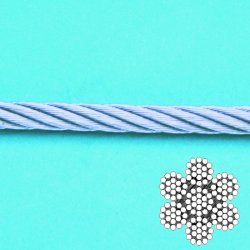

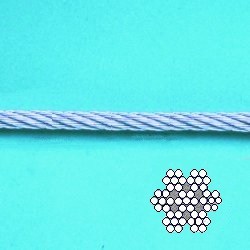

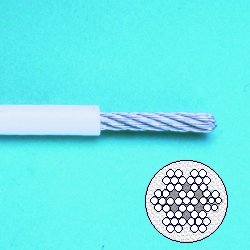

Types of stainless steel wire rope

When it comes to stainless steel wire rope, there are different types available to suit various applications. The two most common types are 1x19 and 7x19. The 1x19 stainless steel wire rope is made up of a single strand of wire with 19 individual wires twisted together. This construction offers excellent strength and minimal flexibility, making it ideal for static applications that require high tensile strength, such as architectural rigging and suspension bridges. On the other hand, the 7x19 stainless steel wire rope consists of seven strands, each made up of 19 individual wires. This construction provides enhanced flexibility, making it suitable for applications that require bending and movement, such as cable railing systems and garage door cables. The 7x19 stainless steel wire rope offers a good balance between strength and flexibility, making it a popular choice for a wide range of applications.

Factors to consider when choosing stainless steel wire rope

Choosing the right stainless steel wire rope for your project involves considering several factors. One of the most important factors is the grade of stainless steel. Stainless steel wire rope is available in different grades, with the most common ones being 304 and 316. The grade of stainless steel determines its resistance to corrosion and other forms of degradation. Grade 304 stainless steel wire rope is suitable for most applications, as it offers good corrosion resistance and is more affordable compared to grade 316. Grade 316 stainless steel wire rope, also known as marine-grade stainless steel, is highly resistant to corrosion and is recommended for applications in harsh environments, such as marine and offshore operations. Apart from the grade of stainless steel, you also need to consider the diameter and configuration of the wire rope. The diameter of the wire rope determines its strength and load-bearing capacity. It is important to choose the right diameter based on the intended application and the load requirements. The configuration of the wire rope refers to the number of strands and wires per strand. Different configurations offer different levels of flexibility and strength, so it is crucial to select the most appropriate configuration for your specific needs.

Understanding wire rope construction and specifications

To fully understand stainless steel wire rope, it is important to familiarize yourself with its construction and specifications. Stainless steel wire rope is made up of individual wires twisted together to form strands, which are then twisted together to form the final wire rope. The number of wires in each strand and the number of strands in the wire rope determine its construction. Wire rope specifications include the diameter, breaking strength, and working load limit. The diameter of the wire rope is measured in millimeters or inches and indicates the thickness of the rope. The breaking strength is the maximum load the wire rope can withstand before it fails. It is crucial to select a wire rope with a breaking strength that exceeds the intended load requirements to ensure safety. The working load limit is the maximum load that the wire rope can safely carry on a continuous basis. It is important to consider the working load limit when selecting the appropriate wire rope for your application to avoid overloading and potential failure.

Proper maintenance and care for stainless steel wire rope

Proper maintenance and care are essential to ensure the longevity and performance of your stainless steel wire rope. Regular cleaning is important to remove dirt, debris, and contaminants that can cause corrosion and compromise the integrity of the wire rope. Use a mild detergent and warm water to clean the wire rope, and rinse thoroughly to remove any residue. Avoid using abrasive cleaners or steel brushes, as they can scratch the surface of the wire rope and promote corrosion. In addition to regular cleaning, lubrication is crucial to reduce friction and prevent wear and tear. Apply a high-quality wire rope lubricant to all the strands and wires, ensuring thorough coverage. This will help to maintain smooth operation and extend the lifespan of the wire rope. It is recommended to lubricate the wire rope after each use and regularly inspect for signs of wear or damage.

Inspection and testing of stainless steel wire rope

Regular inspection and testing are vital to identify any potential issues or defects in the stainless steel wire rope. Inspect the entire length of the wire rope for any signs of wear, corrosion, broken wires, or other forms of damage. Pay close attention to areas where the wire rope is in contact with fittings or sheaves, as these areas are most susceptible to wear and tear. If any defects or damage are detected, it is important to replace the wire rope immediately to ensure safety. Testing the breaking strength of the wire rope is also crucial to verify its integrity and suitability for the intended application. This can be done using specialized equipment to apply a controlled load and measure the wire rope's response. Regular testing should be conducted to ensure the wire rope continues to meet the required load-bearing capacity.

Common applications for stainless steel wire rope

Stainless steel wire rope finds applications in a wide range of industries and projects. It is commonly used in lifting and rigging applications, such as cranes, hoists, and winches, where high strength and durability are essential. Stainless steel wire rope is also widely used in architectural and design projects, such as cable railings, suspension bridges, and artistic installations, where both functionality and aesthetics are important. In the marine and offshore industry, stainless steel wire rope is utilized for various applications, including mooring lines, towing lines, and rigging on boats and offshore structures. The corrosion resistance and durability of stainless steel make it ideal for these demanding environments. Additionally, stainless steel wire rope is commonly used in the food and beverage industry for applications such as conveyor systems, food processing equipment, and wire shelving.

Making the right choice for your wire rope needs

Choosing and maintaining stainless steel wire rope requires careful consideration of various factors, such as grade, construction, diameter, and configuration. By understanding the benefits, types, and specifications of stainless steel wire rope, you can make an informed decision that meets your specific project requirements. Proper maintenance and regular inspection are crucial to ensure the longevity and performance of the wire rope. By following the recommended maintenance practices and conducting regular testing, you can maximize the lifespan and safety of your stainless steel wire rope. When purchasing stainless steel wire rope, opt for reputable suppliers that offer high-quality products and have a strong reputation in the industry. Consider the specific application and load requirements to select the most suitable stainless steel wire rope for your needs. By investing in high-quality stainless steel wire rope and following proper maintenance practices, you can ensure the success and longevity of your project. So, make the right choice and enjoy the strength, durability, and reliability of stainless steel wire rope for your next endeavor.

The Ultimate Guide to Choosing and Maintaining Stainless Steel Wire Rope

Are you looking for the perfect wire rope for your project? Look no further than stainless steel wire rope! With its unparalleled strength and durability, stainless steel wire rope is the ideal choice for a wide range of applications. Whether you need it for lifting heavy loads, securing structures, or even for decorative purposes, stainless steel wire rope provides the reliability and performance you need.

In this comprehensive guide, we will take you through everything you need to know about choosing and maintaining stainless steel wire rope. From understanding different grades and constructions to determining the right size and configuration for your specific needs, we've got you covered. We'll also provide expert tips on proper installation and regular maintenance practices to ensure the longevity and performance of your stainless steel wire rope.

Choosing the right wire rope can make all the difference in the success of your project. So, let us help you navigate the world of stainless steel wire rope and make an informed decision. Read on to discover the ultimate guide to choosing and maintaining stainless steel wire rope.